Pick Up

557. Development of Enzyme-Free Microbial Saccharification Technology to Efficiently and Inexpensively Obtain Glucose from Biomass for the Production of Biofuels and Biochemicals

Greenhouse gas emissions from the agricultural sector amount to 5.41 billion tons per year globally (CO2 equivalent 2017), and have a serious impact on climate change. The enormous amount of agricultural waste generated as a byproduct of large-scale agricultural production and cellulose biomass such as fiber and used paper discarded from our daily lives are difficult to decompose in nature, and the disposal or incineration of such cellulose biomass generates more than 300 million tons of CO2 emissions worldwide.

In order to cope with global climate change and prevent further environmental degradation, it is essential to develop technologies to reduce greenhouse gas emissions, and there is a strong need to establish a sustainable resource management and utilization system that promotes recycling and upcycling of waste materials in order to achieve Japan's 2050 Carbon Neutral Declaration goal.

A joint research group of JIRCAS and King Mongkut's University of Technology Thonburi (KMUTT), Thailand, has been developing a new technology to efficiently and inexpensively obtain glucose, which is necessary for manufacturing biofuels and chemicals, from cellulose-based biomass such as stems, leaves, peels, and lees, as well as food residues, fiber and paper waste, and to produce biofuels and biochemicals

Cellulose is the most abundant resource on earth, but its saccharification has so far required the use of large amounts of cellulase enzymes produced by mold culture. However, cellulase enzymes are difficult to recycle, and their purchase and preparation are costly. In bioethanol production using cellulase enzymes, the cost of cellulose saccharification is the second most expensive cost after the raw material cost, accounting for approximately 30-40% of the production cost, which has been a barrier to its practical application.

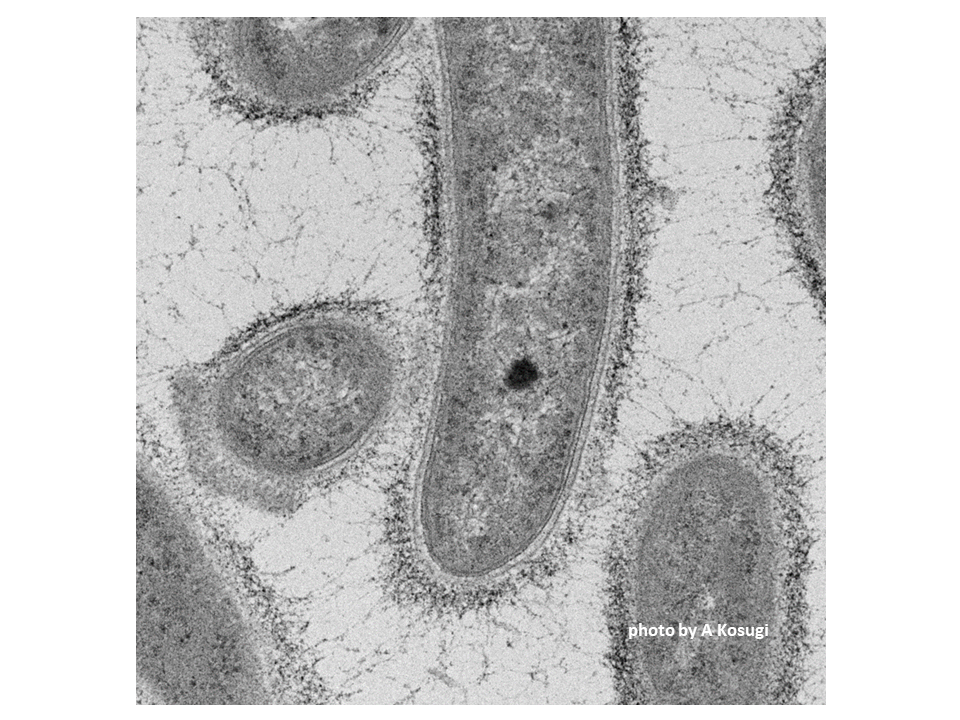

The "microbial saccharification" technology developed by JIRCAS and KMUTT is a revolutionary technology that converts cellulose to glucose using only microbial cultivation, without the need for any enzyme addition. This technology successfully utilizes cellulose-degrading ability, sugar preference, and cellobiose reaction that stops the enzyme from working by culturing cellulose hyper-degrading bacteria and β-glucosidase-producing bacteria together.

The microorganisms can be cultured repeatedly and produce the enzymes necessary for cellulose degradation on their own during propagation, eliminating the need to purchase cellulase enzymes. Since this will reduce costs, it is expected to be applied to materials that have not been recycled, such as waste cotton fiber, which is estimated to amount to about 1.7 million tons per year in Japan.

In addition, in a microbial saccharification experiment using blended fabrics (a mixture of cotton and polyester), only the cotton fiber portion was completely converted to a glucose saccharide solution, confirming that 100% of the polyester resources can be recovered, and the glucose saccharide solution can be recycled into energy, fuel, and plastic materials.

Press release:

https://www.jircas.go.jp/en/release/2022/press202203

Contributors: KOSUGI Akihiko and UKE Ayaka (Biological Resources and Post-harvest Division)