Bacillus aryabhattai produces bioplastics from starch in agricultural residues

Description

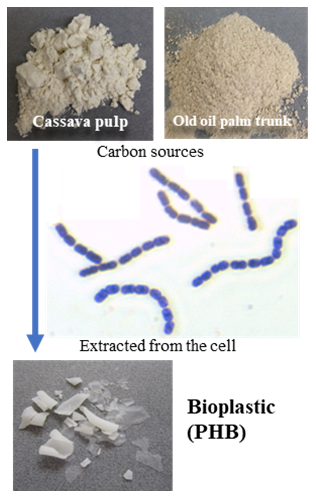

In Southeast Asia, large amounts of agricultural residues such as cassava pulp and oil palm trunk are generated, causing various environmental problems. On the other hand, starch that remained in crop residues is considered as a useful biomass resource. In recent years, the harmful effect of petroleum-based plastics on the environment has been raised in global discussions. Polyhydroxybutyric acid (PHB), a bioplastic material, is expected to become a substitute for petroleum plastics. However, there are some challenges that prevent its widespread use. One big problem is its high production cost, half of which is due to the price of the substrate. The aim of this study, therefore, was to screen for bacteria that can produce PHB, using starch from agricultural waste, in a single step.

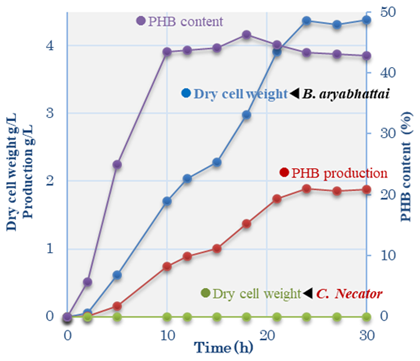

Eighty-four (84) strains of PHB-producing bacteria were isolated from Japanese soil, and Bacillus aryabhattai, the bacterium that produced the largest amount of PHB, was isolated from the screening medium. Because B. aryabhattai retains an amylase gene (amyA), starch can be degraded into glucose by the amylase secreted outside the cells, and the glucose is used as a feed resource to produce PHB and accumulate PHB granules in the cells. When the bacteria were cultured using soluble starch as a carbon source (under optimum conditions considering temperature, pH, starch concentration, etc.), the cell weight was 4.4 g/L, PHB content in cells was 46%, and PHB production was 1.9 g/L.

The above data show that the bacteria exhibit high efficiency in producing PHB from soluble starch (Fig. 1). On the other hand, Cupriavidus necator, which has been used industrially as a PHB-producing bacterium, cannot use starch because it has no amylase gene and cannot produce PHB even when cultured under the same conditions (Fig. 1). When B. aryabhattai was cultured using cassava pulp or starch from oil palm trunk as a carbon source, the cassava pulp starch was degraded by 96% and the oil palm trunk starch by 99%. PHB production was 0.12 g/L and 0.33 g/L, respectively (Fig. 2, Table 1). The weight-average molecular weight, which indicates the physical properties of PHB, was the same as PHB produced using commercially available glucose as a carbon source (Table 2). The melting point, an indicator of heat resistance, was higher than that of PHB produced using commercially available glucose as a carbon source. From these results, the B. aryabhattai PHB is expected to be suitable for heat processing at high temperatures and for increasing the heat resistance of the product.

By using B. aryabhattai, PHB can be produced directly from starch in agricultural residues of cassava pulp and oil palm trunk without using starch-degrading enzymes, thereby reducing the cost of bioplastic production. A reduction in environmental load can be also expected.

Figure, table

-

Fig. 1. PHB production from soluble starch by B. aryabhattai

-

Fig. 2. PHB production from starch in agricultural waste and residues

-

Table 1. PHB production from unused starch in crop residues by B. aryabhattai

Source of starch Starch degradation (%) Dry cell weight (g/L) PHB production (g/L) PHB content (%) Cassava pulp 96±3 1.42±0.08 0.12±0.03 8.68±1.44 Old oil palm trunk 99±1 1.95±0.05 0.33±0.06 17.07±2.83 -

Table 2. Physical property ratio of PHB produced from glucose and cassava pulp by B. aryabhattai and other bacteria

Strain Carbon source Physical properties of PHB Weight‐average molecular weight Number average molecular weight Melting point (℃) B. aryabhattai Glucose 2.19×105 4.43´104 165 Cassava pulp 1.61×105 4.28×104 170 Bacillus spp. 871 Glucose 5.13×105 Unmeasured 153 Bacillus spp. 112A Glucose 5.21×105 Unmeasured 148 Saccharophagus degradans Glucose 5.42×104 Unmeasured 166

- Affiliation

-

Japan International Research Center for Agricultural Sciences Biological Resources and Post-harvest Division

- Classification

-

Technical A

- Program name

- Term of research

-

FY2019 (FY2011-FY2020)

- Responsible researcher

-

Arai Takamitsu ( Biological Resources and Post-harvest Division )

MIERUKA ID: 001768Kosugi Akihiko ( Biological Resources and Post-harvest Division )

Kumar Sudesh ( Universiti Sains Malaysia )

- ほか

- Publication, etc.

-

https://doi.org/10.1080/09593330.2019.1608314

Wichittra B et al. (2019) Environmental Technology, 183:412-425

- Japanese PDF

-

2019_C04_A4_ja.pdf953.5 KB

2019_C04_A3_ja.pdf241.2 KB

- English PDF

-

2019_C04_A4_en.pdf224.27 KB

2019_C04_A3_en.pdf244.71 KB

- Poster PDF

-

2019_C04_poster_fin.pdf324.05 KB