Net energy balance of ethanol production from sap squeezed from old oil palm trunks

Description

In this study, a method was developed to estimate the NER or net energy ratio (i. e., ratio of energy output to energy input) of ethanol production from sap squeezed from oil palm trunks. A bench-scale shredder and compressed mill apparatus was constructed to squeeze the sap containing fermentable sugars from oil palm trunks. Energy input and energy output for squeezing sap were estimated through squeezing trials, and the NER was calculated.

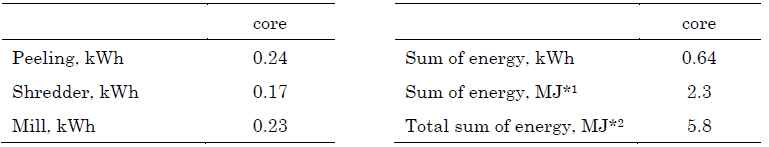

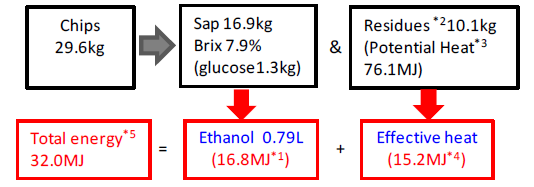

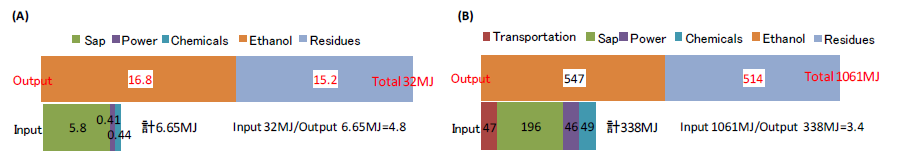

Old oil palm trunks (30-45cm in diameter, 12m in length) were processed into trunk cores (20cm in diameter, 1.2m in length) by peeling the bark and the outer parts. The total amount of energy spent for processing was estimated to be the energy input (Table 1). Energy output, meanwhile, was estimated from the sum of calories derived from ethanol produced from sap and squeezed residues (50% moisture) (Fig. 1). From the study, it was determined that the ratio of energy input to energy output was 4.8 (Fig. 2A).

The energy ratio in ethanol from sugar cane was 8.3 because of self-sufficient energy from bagasse. The energy ratio in ethanol from oil palm sap was also high enough for practical use.

We can estimate the energy from large trunks (40cm in diameter, 10m) by using a multiplying factor of 33.74 on the trunk core.

Energy for transportation was estimated to be 47.2MJ, based on the assumption that the distance from plantation to ethanol plant was 8km (Fig. 2B). On the other hand, energy for cultivation of oil palm was not counted because the materials used were waste products of palm oil production. Likewise, energy for transportation of trunk cores was not counted because the materials used were wastes from the timber factory.

Figure, table

-

Table1. Energy input involved in squeezing sap (core: 20cm in diameter, 1.2m in length)

*1 Conversion kWh to MJ: Wh x 3,600s h-1

*2 MJ = (Sum of energy:2.3MJ) x (100/40) -

-

Fig. 2. The energy involved in sap squeezing.

(A) Trunk core (20cm in diameter, 1.2m in length); (B) Total trunk (40cm in diameter, 10m in length). The energy for transportation from plantation to mill is needed in the case of total trunk.References:

1) Mori, et al. Patent no. 2009-238779

2) Y. Murata, et al. Biomass and Bioenergy 21 (2013): 8-16

- Affiliation

-

Japan International Research Center for Agricultural Sciences Biological Resources and Post-harvest Division

- Classification

-

Research B

- Research project

- Program name

- Term of research

-

FY 2013 (FY 2011-FY 2013)

- Responsible researcher

-

Murata Yoshinori ( Biological Resources and Post-harvest Division )

Arai Takamitsu ( Biological Resources and Post-harvest Division )

MIERUKA ID: 001768Kosugi Akihiko ( Biological Resources and Post-harvest Division )

- ほか

- Publication, etc.

-

Mori, et al. (2009) "Juice method, trunk for a shredder and squeezing system". JP4665257B1

https://doi.org/10.1016/j.biombioe.2012.12.007Y. Murata, et al. Biomass and Bioenergy 51(2013) :8-16

- Japanese PDF

-

2013_C07_A3_ja.pdf237 KB

2013_C07_A4_ja.pdf378.09 KB

- English PDF

-

2013_C07_A3_en.pdf143.44 KB

2013_C07_A4_en.pdf185.51 KB

- Poster PDF

-

2013_C07_poster.pdf295.32 KB