Bio-Ethanol Production from Oil Palm Trunk Fiber.

Description

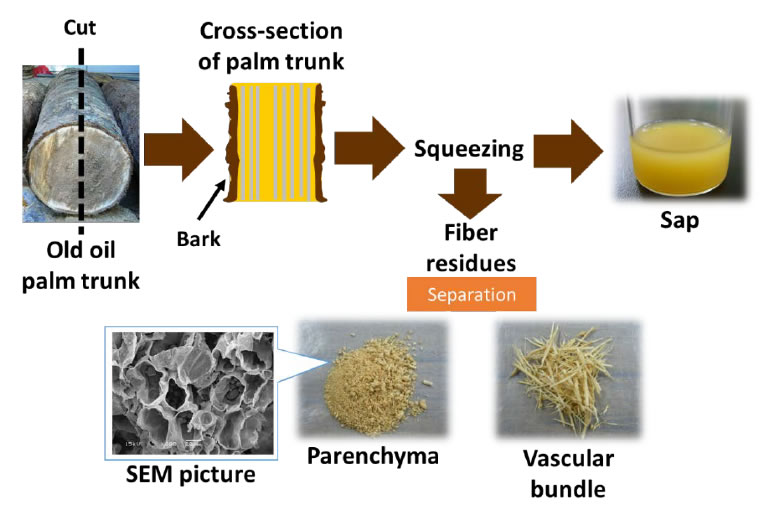

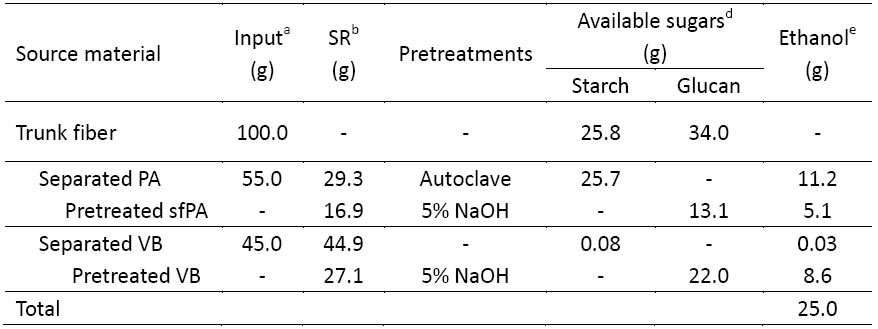

Oil palm (Elaeis guineensis) used in palm oil production must be replanted at 20 to 25-years intervals in order to maintain oil productivity (Yamada et al. 2010). Consequently, the felled palm trunks represent one of the most important biomass resources in Malaysia and Indonesia (Shuit et al. 2009; Sumathi et al. 2008) . To utilize the felled palm trunks specifically for bioethanol production, we characterized the sugars in the sap of the felled trunks and found large quantities of sap with a high glucose content (Kosugi et al. 2010) . This study reports on ethanol production using separated PA and VB from oil palm trunk (Fig.1.). For efficient utilization of cellulosic materials as well as starchy materials, oil palm trunk was separated into PA and VB. Separated PA, alkali-pretreated starch-free PA (sfPA) and VB resulted in high ethanol conversion yields (Table 1). Separated PA and VB from oil palm trunk is a promising fermentation strategy for producing ethanol, without loss of starchy and cellulosic materials (Prawitwong et al. 2012).

Figure, table

-

Fig. 1. Sap and fiber residues from oil palm trunk.

Oil palm trunk was separated into parenchyma and vascular bundle components.

The fractions were easily and distinctly separated. The ratio of PA and VB in the trunk was estimated as approximately 55:45 (dry weight %). -

Table 2. Potential ethanol production from oil palm trunk fiber using a separation process (Prawitwong et al. 2012).

a.Calculated assuming 100 g of squeezed oil palm trunk is used in the separation process.

b.SR (solids remaining) after each pretreatment, calculated from the data in Table 1.

c.Available sugars calculated from the data in each component.

d.Ethanol, calculated from theoretical maximum yield for each saccharification and fermentation.- Kosugi A, Tanaka R, Magara K, Murata Y, Arai T, Sulaiman O, Hashim R, Hamid ZA, Yahya MK, Yusof MN, Ibrahim WA, Mori Y (2010) Ethanol and lactic acid production using sap squeezed from old oil palm trunks felled for replanting. J Biosci Bioeng 110:322-5 doi:10.1016/j.jbiosc.2010.03.001

- Prawitwong P, Kosugi A, Arai T, Deng L, Lee KC, Ibrahim D, Murata Y, Sulaiman O, Hashim R, Sudesh K, Ibrahim WAB, Saito M, Mori Y (2012) Efficient ethanol production from separated parenchyma and vascular bundle of oil palm trunk. Bioresource technology 125:37-42 doi: 10.1016/j.biortech.2012.08.136

- Shuit SH, Tan KT, Lee KT, Kamaruddin AH (2009) Oil palm biomass as a sustainable energy source: A Malaysian case study. Energy 34:1225-1235 doi:10.1016/j.energy.2009.05.008

- Sumathi S, Chai SP, Mohamed AR (2008) Utilization of oil palm as a source of renewable energy in Malaysia. Renewable and Sustainable Energy Reviews 12:2404-2421 doi:10.1016/j.rser.2007.06.006

- Yamada H, Tanaka R, Sulaiman O, Hashim R, Hamid ZAA, Yahya MKA, Kosugi A, Arai T, Murata Y, Nirasawa S, Yamamoto K, Ohara S, Mohd Yusof MN, Ibrahim WA, Mori Y (2010) Old oil palm trunk: A promising source of sugars for bioethanol production. Biomass Bioenergy 34:1608-1613 doi:10.1016/j.biombioe.2010.06.011

- Affiliation

-

Japan International Research Center for Agricultural Sciences Biological Resources and Post-harvest Division

- Classification

-

Research B

- Research project

- Program name

- Term of research

-

FY 2013(FY 2011-FY 2013)

- Responsible researcher

-

Kosugi Akihiko ( Biological Resources and Post-harvest Division )

Prawitwong Panida ( Biological Resources and Post-harvest Division )

Deng Lan ( Biological Resources and Post-harvest Division )

Arai Takamitsu ( Biological Resources and Post-harvest Division )

MIERUKA ID: 001768Murata Yoshinori ( Biological Resources and Post-harvest Division )

- ほか

- Publication, etc.

-

https://doi.org/DOI: 10.1016/j.jbiosc.2010.03.001

Kosugi, A. et al. (2010) J. Biosci. Bioeng, 110: 322–325

Patent: JP2013188748 (A) - SEPARATOR BODY AND SEPARATION METHOD FOR SOLID MIXTURE https://www.jircas.go.jp/en/patent/JP2013188748

https://doi.org/10.1016/j.biortech.2012.08.136Prawitwong, P. et al. (2012) Bioresource Technology, 125: 37–42

Patent: JP2011224479 (A) - Water absorbent material https://www.jircas.go.jp/en/patent/JP2011224479

- Japanese PDF

-

2013_C06_A3_ja.pdf188.72 KB

2013_C06_A4_ja.pdf338.86 KB

- English PDF

-

2013_C06_A3_en.pdf168.01 KB

2013_C06_A4_en.pdf736.24 KB

- Poster PDF

-

2013_C06_poster.pdf316.01 KB