Production of biodegradable plastic from oil palm sap

Description

Biodegradable plastic (or bioplastic) are commonly produced from corn starch and edible oil. However, the aforementioned raw materials are also important food components, which could lead to competition between the bioplastic and food industries for the same resources.

Palm oil is a common agricultural product in Southeast Asia. Its source--the oil palm trees--has an economic life span of approximately 20-25 years, after which old trees are felled and the farms, replanted. Meanwhile, the discarded oil palm trunks are suddenly available in large quantities, providing readily-available alternative sources for new products such as bioplastic. These renewable resources derived from agricultural wastes are also called “waste agricultural biomass” or “biomass resources.”

From previous studies, it was shown clearly that ethanol and lactic acid were efficiently producible from oil palm sap using yeast and lactic acid bacteria. It was also found that the concentration of fermentable sugars in the trunk can be drastically increased within a suitable storage period. The polymer that was produced, called Poly-3-hydroxbutyrate (PHB), shows excellent heat resistance and biodegradability, and the expanding demand is expected along with polylactic acid. The objective of this study, therefore, is the development of cheap and efficient PHB-producing techniques from oil palm sap.

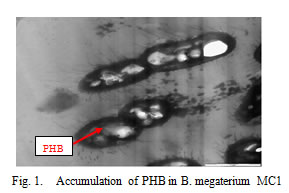

Poly-3-hydroxbutyrate (PHB) was produced from sugar in oil palm sap using B. megaterium MC1 for the first time (Fig. 1). Different sap sugar concentrations were added to the production medium to analyze its effect on PHB biosynthesis. Sap sugar concentration ranging from 1.0 to 2.5% w/v was tested. With 2.5% w/v sap sugar concentration, a maximal PHB concentration of 1.91 g/L was recorded at 12h of growth (Fig. 2). Nitrogen plays an important role in influencing the process of PHB accumulation in bacterial cells. Different nitrogen compounds were used in this experiment to study the effect of these nitrogen sources on B. megaterium MC1. Urea is efficient and economical to produce PHB as a source of nitrogen. Ratio of carbon and nitrogen (C/N molar ratio) in medium has been seen as one of the important factors influencing the biosynthesis of PHB in cell. With a fixed amount of carbon, different C/N ratios were tested by varying the urea concentration. A maximal PHB concentration was obtained with a C/N ratio of 50. To enhance PHA production, B. megaterium MC1 was grown in optimum condition. PHB of 3.28 g/L was produced from the juice liquid containing sugar of 2.5 % after 16 hours (Fig. 3)

Figure, table

- Affiliation

-

Japan International Research Center for Agricultural Sciences Biological Resources and Post-harvest Division

- Classification

-

Administration B

- Research project

- Program name

- Term of research

-

FY 2011 (FY 2011-FY 2015)

- Responsible researcher

-

Arai Takamitsu ( Biological Resources and Post-harvest Division )

MIERUKA ID: 001768Kosugi Akihiko ( Biological Resources and Post-harvest Division )

Mori Takashi ( Biological Resources and Post-harvest Division )

Murata Yoshinori ( Biological Resources and Post-harvest Division )

Lokesh B. E. ( Universiti Sains Malaysia )

- ほか

- Publication, etc.

-

Kosugi, et al. (2010) "Method for producing ethanol and lactic acid". JP2007015127A

Lokesh et.al. (2012) CLEAN 40(3):310-317

- Japanese PDF

-

2011_14_A4_ja.pdf258.62 KB

- English PDF

-

2011_14_A4_en.pdf204.24 KB