New approach for Tartary buckwheat utilization by rapid heating treatment

Description

Tartary buckwheat (Fagopyrum tataricum Gaertn.) is widely known as a functional food/medicinal source throughout the world. A relatively low-demanding crop, Tartary buckwheat can tolerate environmental stresses such as water deficiency, diseases, insects, and ultraviolet radiation, thus it is often used in organic farming systems and as an emergency crop around the world. Tartary buckwheat is anticipated to be utilized for various food products due to its high rutin content, indicating high potential in terms of functional benefits. However, its utilization is limited owing to the difficulty in dehulling its hard pericarp and the strong bitterness of its products, which in turn are attributed to quercetin formation by rutinosidase-induced rutin hydrolysis in buckwheat seed. In addition, enzyme activity in Tartary buckwheat is strong enough to hydrolyze rutin to quercetin in a very short time, comparable with that of common buckwheat. Thus, products using Tartary buckwheat as an ingredient are strongly bitter in taste even if mixed with common buckwheat, which is otherwise not bitter.

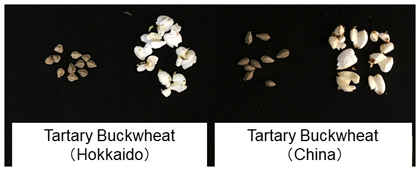

This study therefore aimed to develop an effective treatment to overcome both the limitations of dehulling and rutinosidase activity in Tartary buckwheat utilization by circulated fluidized-bed heating. Using a circulated fluidized-bed at high temperatures, the treatment enabled buckwheat to produce a popcorn-like gelatinized product (Fig. 1). Also, although rutin was mostly retained in the samples, the products did not exhibit bitterness and their functionality was conserved (Table 1). Owing to the denaturation of rutinosidase in the heat-treated products, rutin content in the model system (i.e., Tartary buckwheat mixed with common buckwheat) was retained without the formation of the bitter digested product, quercetin (Fig. 2). Nutritional analysis of pre- and post-treated products showed retention of the macronutrients even after heat treatment. The popped Tartary buckwheat could, therefore, be obtained by simple treatment, and might reveal new opportunities to utilize pre-gelatinized and rutin-rich properties by rutinosidase denaturation (Table 2).

Regarding this treatment’s utilization and future prospects, its biggest advantage is that it broadens the utilization of Tartary buckwheat as a simple and low-cost functional food source. The final edible product contains high rutin without bitterness and rutinosidase activity. Furthermore, the model study showed the possibility of using the popped Tartary buckwheat as an intermediate product, providing high amounts of rutin to various foods, such as bread, steamed bun, and buckwheat noodle, as a mixture ingredient. The treatment curtails production cost by rapid heating in a circulated fluidized-bed, and it does not require high-pressure processing.

Figure, table

-

Fig. 1. Popped Tartary buckwheat using circulated fluidized-bed heating treatment

The treatment provides edible popped Tartary buckwheat in a short time. -

Table 1 Rutin content of samples with/without the treatment (dry matter basis)

Sample name Treatment Rutin

(㎎/100g)Tartary

Buckwheat

(Hokkaido)Unpopped 1,637±118.2 Popped 1,469±49.5 Tartary

Buckwheat

(China)Unpopped 1,548±77.8 Popped 1,202±72.2 Rutin was slightly decreased; however, the product did not show bitterness from the rutin-degraded product, quercetin

-

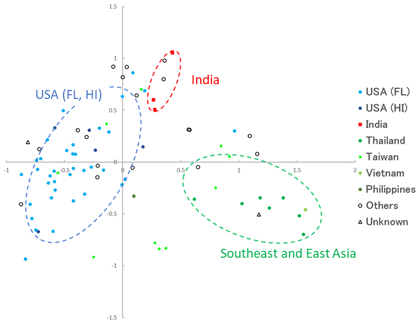

Fig. 2. Chromatograms of rutinosidase assay mixtures using crude enzymes

The assays were performed with crude enzyme from Tartary buckwheat samples with rutin, then the substrate (rutin) and product (quercetin) were quantified. -

Table 2 Macronutrients in Tartary buckwheat samples (Hokkaido)

Sample name Treatment Protein

(g/ 100g)Fat

(g/ 100g)Ash

(g/ 100g)Carbohydrate

(g/ 100g)Fiber

(g/ 100g)Energy

(kcal/ 100g)Tartary buckwheat

(Hokkaido)Unpopped 13.7 4.1 2.3 79.9 5.7 411 Popped 12.5 4.0 2.2 81.3 4.5 411

- Affiliation

-

Japan International Research Center for Agricultural Sciences Biological Resources and Post-harvest Division

- Classification

-

Technical A

- Research project

- Program name

- Term of research

-

FY2019 (FY2016-FY020)

- Responsible researcher

-

Fujita Kaori ( Biological Resources and Post-harvest Division )

Tadashi Yoshihashi ( Biological Resources and Post-harvest Division )

- ほか

- Publication, etc.

-

https://doi.org/10.3136/fstr.25.613

Fujita K. and Yoshihashi T. (2019), Food Science and Technology Research 25 (4): 613-618

- Japanese PDF

-

2019_C02_A4_ja.pdf639.37 KB

2019_C02_A3_ja.pdf243.19 KB

- English PDF

-

2019_C02_A4_en.pdf351.68 KB

2019_C02_A3_en.pdf291.83 KB

- Poster PDF

-

2019_C02_poster_fin.pdf356.04 KB