Extraction of p-hydroxybenzoic acid, a promising raw material for plastics, from oil palm biomass

Description

Malaysia is one of the world’s leading producers of palm oil. Huge amounts of residues like empty fruit bunches (EFBs), kernel shells (accumulated in mills), fronds and trunks (left at plantation fields) are generated from oil palm (Elaeis guineensis Jacq., Arecaceae). Low-molecular-weight phenolic compounds (LMPCs) extracted from subcritical water treatment of oil palm biomass has shown promise as a raw material for producing plastics, thereby promoting the efficient use of waste resources. In this study, the LMPC yield for each part of the oil palm was clarified.

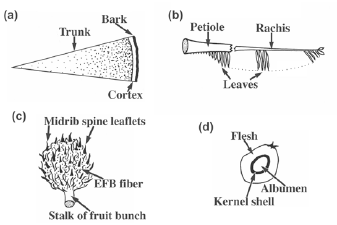

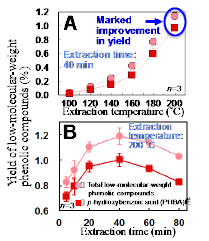

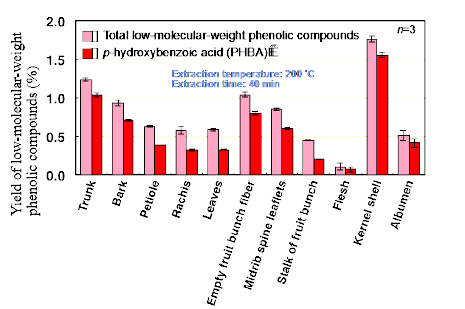

An oil palm plant sample was divided into 11 parts for use as residue materials for extracting LMPC [e.g., p-hydroxybenzoic acid (PHBA)] (Fig. 1). We carried out subcritical water extraction of the oil palm trunk and the condition of transformation/extraction was optimized for a given combination of temperature and time. In contrast to supercritical water extraction, which causes pyrolysis, subcritical water extraction possesses a high hydrolytic ability. PHBA is a native constituent in oil palm, and its yield markedly increases with the degradation of ester linkages in high-molecular-weight secondary metabolites (Fig. 2A). Evaluations showed that the kernel shell had the highest PHBA yield. In comparison, the frond (including leaves, petiole, and rachis) was evaluated as superior, in consideration of the resource amount being up to six times that of EFB or trunk, although the PHBA yield from this part is not very high (Fig. 3).

Subcritical water treatment is an environmentally friendly method of extracting phenolic constituents because it does not require organic solvents, acids, alkalis, and so on. It can be performed if there is a pressure-tight container, which can withstand high temperatures of about 200–250°C, and a temperature controller. Subcritical water extraction, therefore, has an advantage in terms of equipment cost and energy consumption. There is a huge amount of residue resources, particularly fronds; however, there are few utilization methods available at present. In this study, the potential of fronds was appreciated from LMPC yield data and resource amount for each part of the oil palm. The kernel shell, on the other hand, exhibited the highest PHBA and LMPC yields. Although the resource amount is less than that of fronds, it was classified accordingly as available raw material because palm kernel shells are regularly accumulated in palm oil mills as wastes.

Figure, table

-

Fig.1. Parts of the oil palm(a: cross-section of trunk, b: frond, c: empty fruit bunch, d: cross-section of fruit)

-

Fig.2. Effect of temperature (A) and time (B) on the yields of low-molecular-weight phenolic compounds from oil palm trunk during subcritical water extraction

-

Fig. 3. Yields of low-molecular-weight phenolic compounds from each part of oil palm

- Affiliation

-

Japan International Research Center for Agricultural Sciences Forestry Division

- Classification

-

Research B

- Research project

- Program name

- Term of research

-

FY 2012 (FY 2006-FY 2010、FY 201-FY2012)

- Responsible researcher

-

Kawamura Fumio ( Forestry and Forest Products Research Institute )

KAKEN Researcher No.: 80353655Hashim Rokiah ( Universiti Sains Malaysia )

Sulaiman Othman ( Universiti Sains Malaysia )

Saary Nur Syahirah ( Universiti Sains Malaysia )

- ほか

- Publication, etc.

-

https://doi.org/10.6090/jarq.48.355

Kawamura F. et al. (2014) Japan Agricultural Research Quarterly, 48(3):355–362.

Kawamura F. (2008) Green Spirits, 4(3):10–13

- Japanese PDF

-

2014_C08_A3_ja.pdf228.64 KB

2014_C08_A4_ja.pdf225.28 KB

- English PDF

-

2014_C08_A3_en.pdf163.84 KB

2014_C08_A4_en.pdf244.21 KB

- Poster PDF

-

2014_C08_poster.pdf449.4 KB