Changes in location and structure of underground pipes enhance water vapor collection in plastic film tunnels

Description

Agriculture is the largest water user, with 70% of the world’s freshwater withdrawn for irrigation. Ishikawa et al. (1996) developed an “earth-air heat exchange water distillation system” that can produce freshwater by collecting water vapor in a plastic film tunnel as condensed water on the insides of the plastic film and underground pipes. Their system successfully collected 30% of the evaporated water. This study aimed to develop a simple water distillation system constructed from agricultural materials, suitable for installation in rural areas, while improving the earth-air heat exchange water distillation system to enhance water vapor collection.

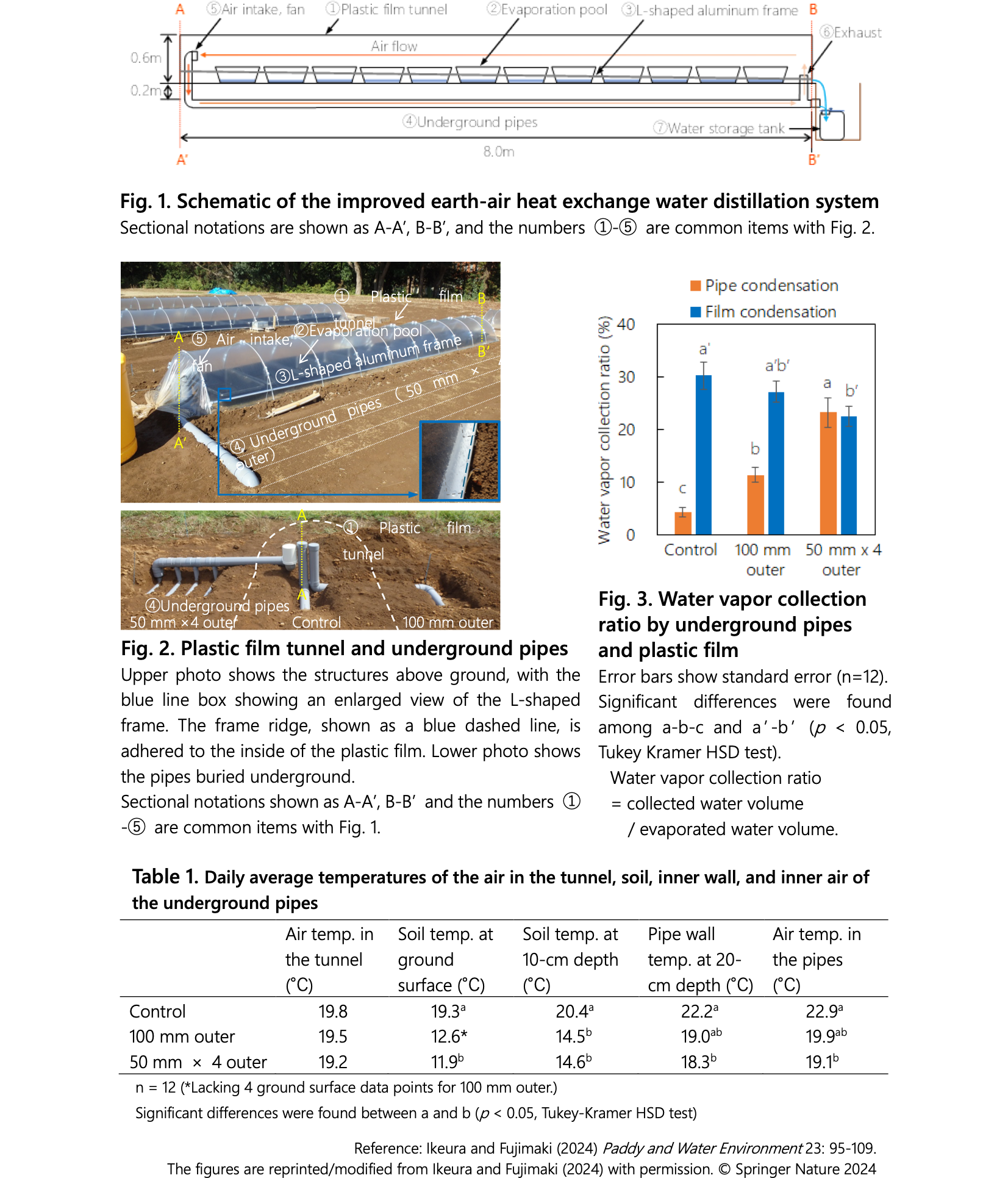

Three plastic film tunnels (1.2 m wide, 0.6 m high, 8.0 m long) were built, and three types of underground pipes were embedded at 20 cm depth below ground: i) one PVC pipe with a diameter of 100 mm below the tunnel (control; Ishikawa model), ii) one PVC pipe with a diameter of 100 mm outside the tunnel (100 mm outer), and iii) four PVC pipes with diameters of 50 mm outside the tunnel (50 mm × 4 outer). Different underground pipes were selected for each tunnel and rotated for the next trials. Water tubs serving as evaporation pools were put in the tunnels, and the water in the pools was heated by solar radiation and evaporated. Hot and humid air was blown into the pipes by a fan with a solar panel, and water vapor was cooled by soil temperature around the underground pipes and condensed on the inside of the pipes. The water vapor in the tunnel was cooled by ambient air, and condensed water on the inside of the plastic film was collected by L-shaped aluminum frames placed under the plastic film on both sides of the tunnel. The collected freshwater was stored in tanks at the tail end of the tunnel (Figs. 1 and 2).

Soil temperature at the ground surface, pipe wall temperature, and air temperature in the pipes embedded outside the tunnel tended to be lower than those of the control. In particular, the pipe wall temperature of 50 mm × 4 outer was significantly lower than the control (Table 1). In the case of 50 mm × 4 outer, 12.4 L of freshwater was produced from one tunnel on a sunny day in March in Tsukuba, Ibaraki, Japan. The water vapor collection ratio, defined as the ratio of collected water volume to evaporated water volume, for the pipes of the control, 100 mm outer, and 50 mm × 4 outer was 4.3%, 11.3%, and 23.3%, respectively (shown as the orange color bar in Fig. 3). The water vapor collection ratios for the plastic films were 30.3% using the control, 27.2% using 100 mm outer, and 22.5% using 50 mm × 4 outer (shown as the blue color bar in Fig. 3). The total collection ratio for both the pipes and plastic film of 50 mm × 4 outer was 46%, which was 1.3- and 1.2-times higher compared to the control and 100 mm outer, respectively.

Figure, table

- Program name

- Term of research

-

FY2022

- Responsible researcher

-

Ikeura Hiroshi ( Rural Development Division )

Fujimaki Haruyuki ( Tottori University )

ORCID ID0000-0003-0175-1773KAKEN Researcher No.: 90323253 - ほか

- Publication, etc.

-

Ikeura H. and Fujimaki H. (2024) Paddy and Water Environment.https://doi.org/10.1007/s10333-024-01001-8

- Japanese PDF

-

2024_A11_ja.pdf1.16 MB

- English PDF

-

2024_A11_en.pdf924.52 KB

* Affiliation at the time of implementation of the study.