Scalable Research Achievement

Liquefaction of Thai fermented rice noodles can be prevented by maintaining the product in acidic condition of pH around 4

Description

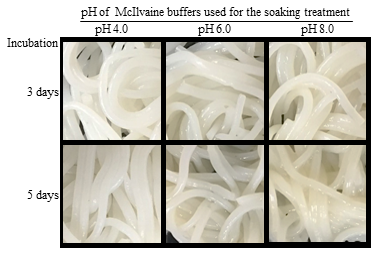

Fermented rice noodles, traditionally known as khanom jeen in Thailand, are produced and consumed countrywide. Similar types of products are common in Laos, Vietnam, Cambodia, Myanmar, and China. Khanom jeen is made from fermented rice flour containing lactate. In the noodle factories, the fermented rice flour is heated to achieve partial starch gelatinization and kneaded with water. The dough is then extruded into noodles in boiling water for about one minute, washed with water, drained using a sieve container, and sold. The fermented rice noodles have a unique and preferable flavor and texture achieved through the rice fermentation process. Normally, the products retain quality without rotting for a few days at ambient temperature. Refrigeration is not applicable to the noodles because starch retrogradation at cold temperatures ruins the unique texture. However, it occasionally suffers from severe liquefaction (Fig. 1) before the products are sold in the market. Although the direct cause has yet to be clarified, an urgent solution to the liquefaction problem is needed to reduce economic and food losses.

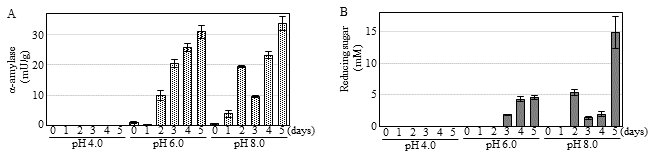

Liquefaction is thought to result from water release associated with digestion of the starch maintaining the noodle structure by amylolytic enzymes with pH preferences for activity. The fermented rice noodles containing 0.03% lactate is acidic with a pH of 3.7. The pH changes to 4.0, 6.0, or 7.7 after soaking in McIlvaine buffers at pH 4.0, 6.0, or 8.0 for 10 min, respectively. Moisture transudation and partial liquefaction are observed in noodles treated with buffers at pH 6.0 or 8.0 after 3 to 5 days of incubation at 37°C (Fig. 2). In contrast, such phenomena are not observed in noodles treated with buffer at pH 4.0 (Fig. 2) or in those treated with buffer containing 200 μg/mL chloramphenicol (data not shown), indicating that liquefaction of fermented rice noodles is induced, accompanied by bacterial growth in products in which the pH is heightened to 6.0 or higher. α-amylase activity is detected in noodles treated with buffers at pH 6.0 or 8.0 after 2 days or 1 day of incubation, respectively (Fig. 3A). An increase in reducing sugar is observed in accordance with α-amylase production under liquefaction-inducing conditions (Fig. 3B). It is presumably derived from oligosaccharides by starch digestion in noodles. Taken together, it is important for the producers to maintain fermented rice noodles as well as fermented rice flour in acidic condition of pH around 4 to prevent liquefaction of the products.

The producers can monitor the pH of their products by using a food-grade pH meter or with the simplified method using pH-test papers. It is also recommended that the producers check the pH of the water for washing the fermented rice noodles at the end of production. Underground water, which is generally used for the washing stage, might be alkalized due to soluble minerals. Edible organic acids such as acetate can be used to adjust the pH of the washing water, although the usage needs to be carefully optimized in consideration of the flavor of the product. Information regarding liquefaction prevention and the manufacturing process, as well as serving ideas for fermented rice noodles, are simply summarized in a booklet in Thai (Fig. 4). It would be useful not only to the producers but also the general public, and it is expected to increase productivity, improve the food value chain, and raise awareness on this great local food tradition.

Figure, table

-

Fig. 1. Liquefaction of fermented rice noodles

-

Fig. 2. Appearance of fermented rice noodles after 3 and 5 days of incubation at 37°C after soaking treatment with McIlvaine buffers at pH 4.0, 6.0, and 8.0

-

Fig. 3. Time-dependent change in α-amylase activity (A) and reducing sugar content (B) in fermented rice noodles treated with McIlvaine buffers at pH 4.0, 6.0, and 8.0

-

Fig. 4. Cover illustration (A) and introduction of pH monitoring methods (B) in a booklet on fermented rice noodles, written in Thai

- Affiliation

-

Japan International Research Center for Agricultural Sciences Biological Resources and Post-harvest Division

- Classification

-

技術

- Research project

- Program name

- Term of research

-

FY2019 (FY2016-FY2020)

- Responsible researcher

-

Marui Junichiro ( Biological Resources and Post-harvest Division )

MIERUKA ID: 001765Tadashi Yoshihashi ( Biological Resources and Post-harvest Division )

Shompoosang Sirinan ( Institute of Food Research and Product Development, Kasetsart University, Thailand )

Surojanametakul Vipa ( Institute of Food Research and Product Development, Kasetsart University, Thailand )

- ほか

- Publication, etc.

-

https://doi.org/10.6090/jarq.54.41

Marui J et al. (2020) Japan Agricultural Research Quarterly, 54(1):41-45

- Japanese PDF

-

2019_C01_A4_ja.pdf591.61 KB

2019_C01_A3_ja.pdf352.63 KB

- English PDF

-

2019_C01_A4_en.pdf270.23 KB

2019_C01_A3_en.pdf315.55 KB

- Poster PDF

-

2019_C01_poster_fin.pdf429.71 KB