Production of binderless particleboard and compressed lumber using oil palm trunk as a feedstock

Description

Palm oil, which is produced from fruit of oil palm (Elaeis guineensis), is one of the most important agricultural products in Southeast Asia, particularly in Malaysia and Indonesia. Oil palm is replanted every 25 to 30 years for to maintain the fruit production, and a large amount of biomass, namely oil palm trunk (OPT), is generated when they are felled. At present, this trunk is not efficiently used. On the other hand, for wood-based industries, the shortage of wood from natural forests is becoming a major concern. So research has been actively undertaken on unutilized biomass for to find substitute for some existing usages and decrease the demand for limited natural resources. Considering such situations, we have developed two types of products using OPT as a feedstock, namely binderless particleboard and compressed lumber.

Binderless particleboard is a self-binding particleboard without the addition of adhesives. It is produced simply by hot pressing formed particles at appropriate temperature and pressure. Since it does not used synthetic adhesives, cost necessary for raw materials and impact toward environment is smaller, compared with typical particleboard with synthetic adhesives. Also, by reducing feedstock to particles, it is assumed to overcome heterogeneity of OPT depending on the section of that used (interior or exterior; bottom or top). The binderless board produced by laboratory scale experiment is shown in Fig. 1. Under the conditions we have tried, the physical properties of board become maximum at the press temperature 200 °C.

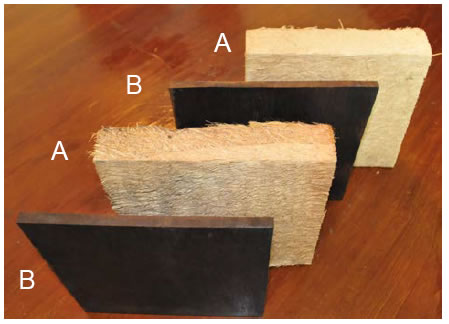

Compressed lumber is the densified board produced by hot pressing block of feedstock. Normally in the case of wood, the strength of the product enhances by this densification. This was also valid for compressed lumber made from OPT. The compressed lumbers produced are shown in Fig. 2. A steam process in a closed chamber at a temperature of 130 °C before compression made physical properties and dimensional stability better than those without the process.

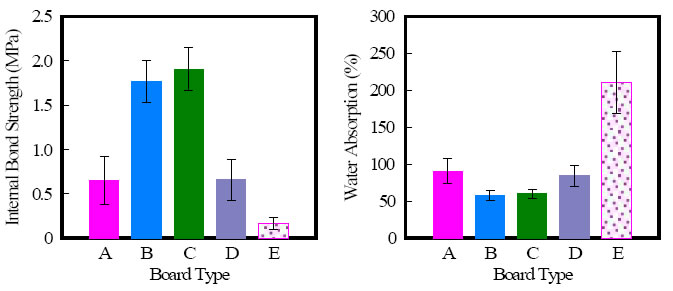

Unlike wood, the main components of which are cellulose, hemicellulose and lignin, OPT also contains sugars and starch at certain levels as sap or in parenchyma tissues. When binderless particleboards were produced with monomeric and dimeric sugars extracted OPT, properties of the board obtained was inferior to the board made from non-extracted sample (Fig. 3). On the other hand, addition of glucose and sucrose increased properties of the produced board. Since such effects were not observed with starch added sample, it is suggested that such sugars in sap contribute to self-binding mechanism of binderless particleboard and probably to features of compressed OPT lumber.

Regarding OPT binderless particleboard, the weak point is water durability. So at moment, the board should be used for indoor use, such as interior finishing or furniture.

Figure, table

-

Fig. 1. Image of the binderless particleboard made from oil palm trunk

(The magnified image of the surface is shown inside the circle.) -

Fig. 2. Image of the compressed lumber made from oil palm trunk (B)

(A: The raw material before compression.) -

Fig. 3. Internal bond strength (left) and water absorption (right) of various types of board

(A: unextracted OPT board (control), B: unextracted + 20% glucose board, C: unextracted + 20% sucrose board, D: unextracted + 20% starch board, E: extracted OPT board)

- Affiliation

-

Japan International Research Center for Agricultural Sciences Forestry Division

- Classification

-

Research A

- Research project

- Program name

- Term of research

-

FY 2012 (FY 2006-FY 2010、FY 2011-FY 2012)

- Responsible researcher

-

Sugimoto Tomoko ( Forestry Division )

KAKEN Researcher No.: 20353732Hashim Rokiah ( Universiti Sains Malaysia )

Sulaiman Othman ( Universiti Sains Malaysia )

Sato Masatoshi ( University of Tokyo )

KAKEN Researcher No.: 90302588 - ほか

- Publication, etc.

-

https://doi.org/10.1016/j.matdes.2011.01.053

Hashim, R. et al. (2011) Materials and Design, 32: 2520-2525

Said, N. et al. (2013) In: L. Rajamani and N. Esa eds. The relevance of science to local knowledge. Penang: Penerbit USM, 42-47

https://doi.org/10.1007/s00107-013-0712-5Boon, J. G. et al. (2013) Eur. J. Wood Prod., 71: 583-589

Salim, N. et al. (2013) BioResources, 8 (2): 2310-2324

Sugimoto, T. et al. (2013) JIRCAS Working Report No. 80: 51-57

Biomass Utilization in Tropical Asia: Past, Present and Future

- Japanese PDF

-

2013_C08_A3_ja.pdf217.76 KB

2013_C08_A4_ja.pdf384.44 KB

- English PDF

-

2013_C08_A3_en.pdf103.3 KB

2013_C08_A4_en.pdf135.13 KB

- Poster PDF

-

2013_C08_poster.pdf292.94 KB